Our expertise in plastics processing

We are a plastics processing company specializing in the production of textile braid finishes by overmolding or injection, for technical use (automotive equipment, medical equipment, luggage, boating, etc.). Our production chain extends from the design of the plastic part using 3D modeling, through to mass production, either in-house or as an industrial subcontractor.

All our plastic parts are 100% French-made, from our production workshop in Ambert (63) in Auvergne.

We are equipped to carry out a wide range of tests, to ensure that our products meet your specifications in every respect.

Our quality process is validated by ISO 9001 version 2015 certification.

Our plastics specialists are at your disposal for all your custom plastic part design and manufacturing projects.

Engineering and design

Our design office can create small plastic parts using 3D modeling, based on drawings or models.

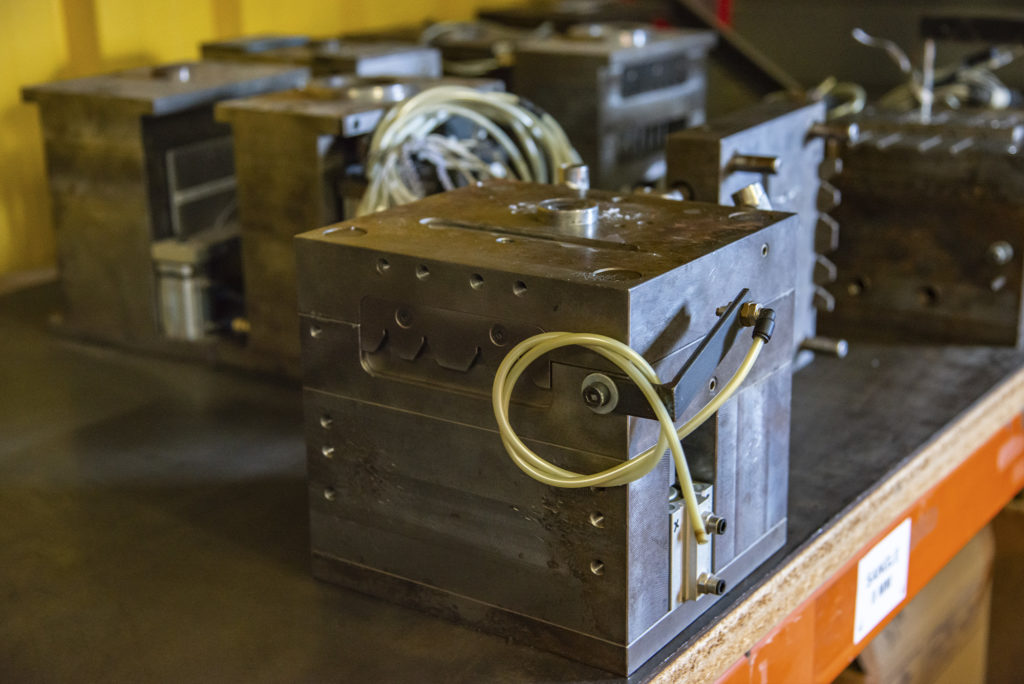

We also design molds for the production of prototype parts, as well as small, medium and large production runs. Molds can be fitted with a punch to mark each part with a brand name or logo.

Textile overmolding

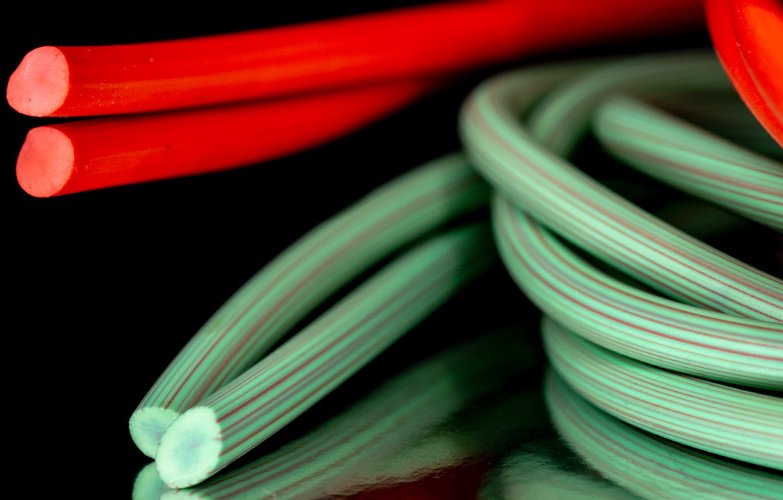

Overmolding on narrow textiles is a speciality of our company, validated by years of expertise in plastics processing.

From a mold developed by our technical team or supplied by our customers, we overmold any type of braid or cord to add endcaps, loops, handles, hooks and other technical finishes.

Plastic injection

Plastic injection on our horizontal and vertical injection molding machines enables us to rapidly manufacture customized plastic parts to strict specifications, for any automotive, decoration, interior design or DIY project.

We are able to work with a wide range of thermoplastics and elastomers: POM, PA, PVC, PE, TPE… to produce plastic parts of different sizes and colors, with the hardness required by the specifications, by injection or micro-injection.

Plastic extrusion

On request, we manufacture tubes, rods and profiles by plastic extrusion, according to your specifications.

Our extrusion processes enable us to supply protective sheaths, rigid or flexible rods and plastic profiles for the automotive, interior design and decoration, chemical and medical industries.