3D printing prototyping

To complete our range of services, we have acquired a 3D printer for rapid prototyping and very small series production. 3D printing makes it possible to produce complex parts from CAD files, easily and in record time.

Like plastic injection molding, this technology uses thermoplastic material, heated and shaped to create parts. The big difference is that there’s no need for a mold, which means you can keep your budget under control, produce prototypes quickly, and correct them just as quickly.

It’s a very interesting process for functional prototyping, as it enables several product versions to be created at no extra cost, until a valid model is obtained that conforms to specifications.

In addition, 3D printing can be used to manufacture small or very small series of parts in a very short time, without monopolizing a production line.

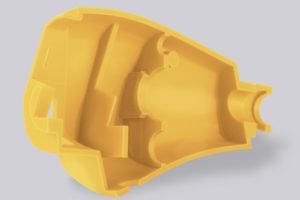

Our 3D printer can create parts up to 300 x 300 x 400 mm, in a wide range of materials (PLA, TPU, ABS, PLA wood, PVA, HIPS…). Technical parts, decorative objects, models, plastic accessories: a wide range of parts can be produced.

Our team is at your disposal for any 3D printing prototyping or small series production project. Please do not hesitate to contact us.

Examples of possible 3D printing creations (non-contractual photos)