Overmolding

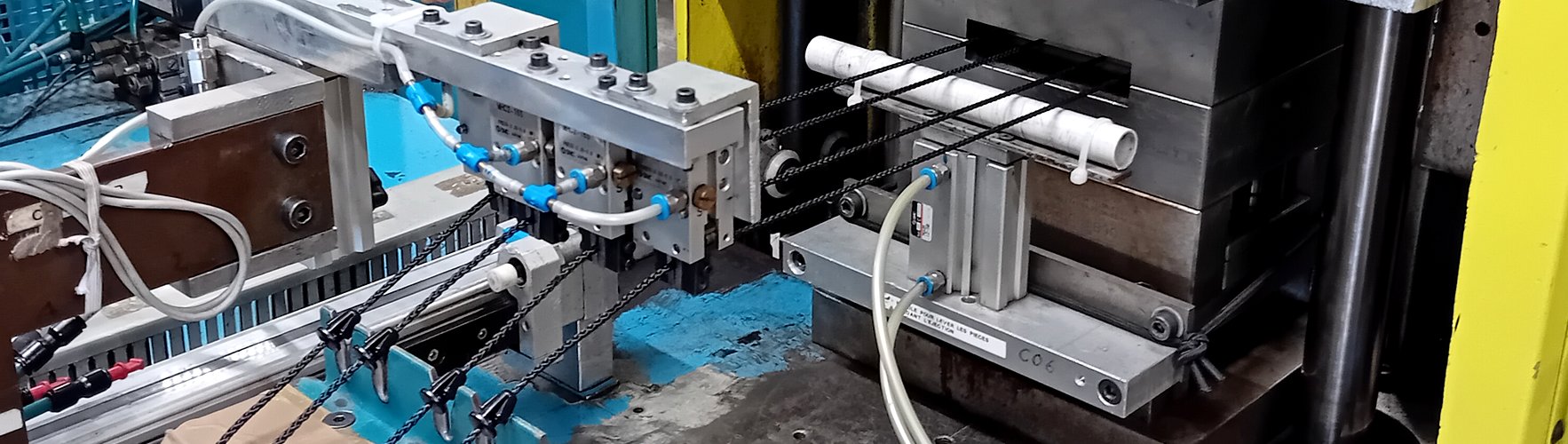

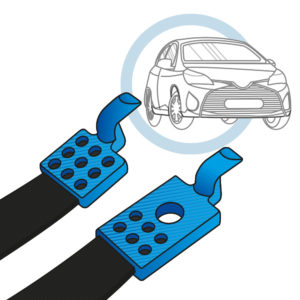

Plastic overmolding on narrow textiles is our specialty ! This plastics processing technique, also known as injection molding, involves injecting thermoplastic material into a mold, then ejecting it directly onto a textile braid or cord.

In this way, the integrity of the textile is not altered, and a robust, ready-to-use overmolded article is obtained, without the need for assembly. This manufacturing process also saves time, by automating the process and producing large quantities of parts, from small to large runs, with perfect reproducibility.

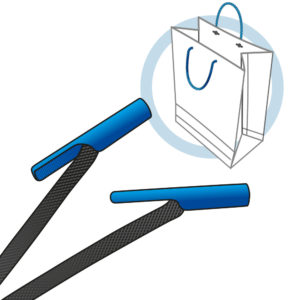

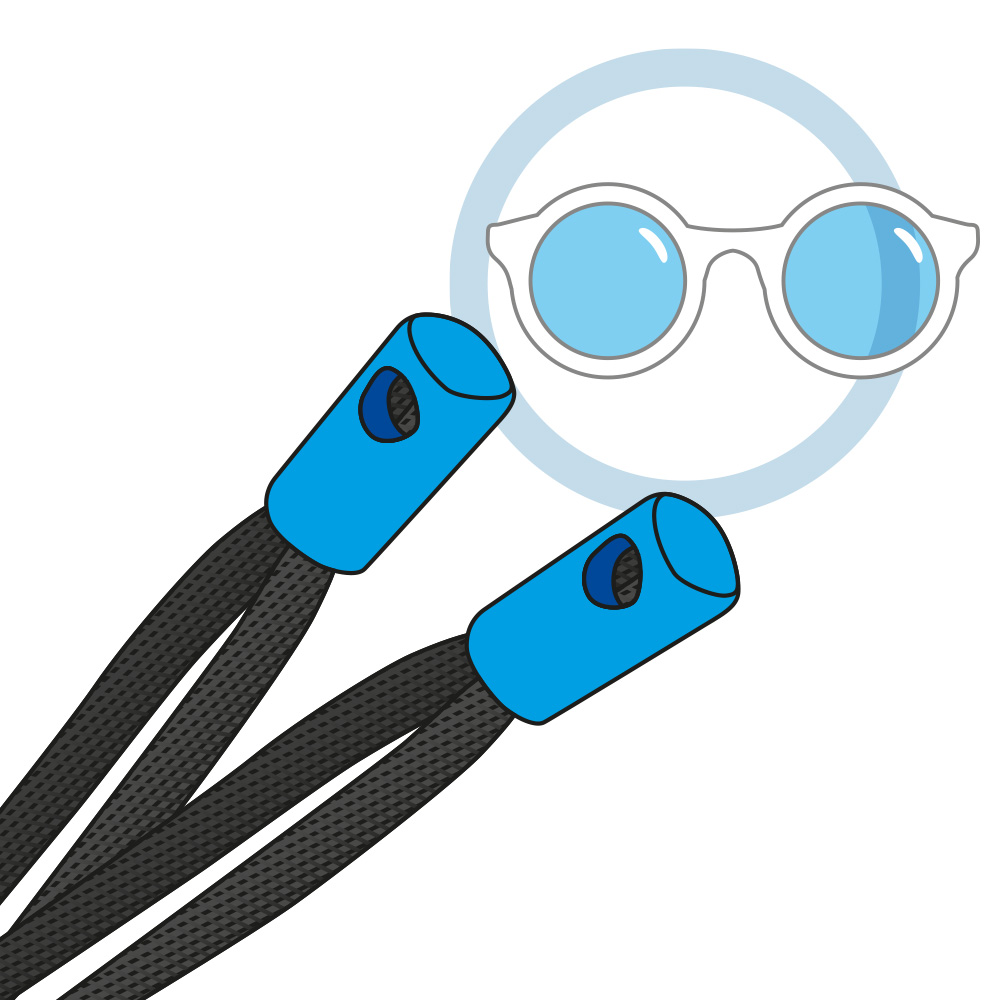

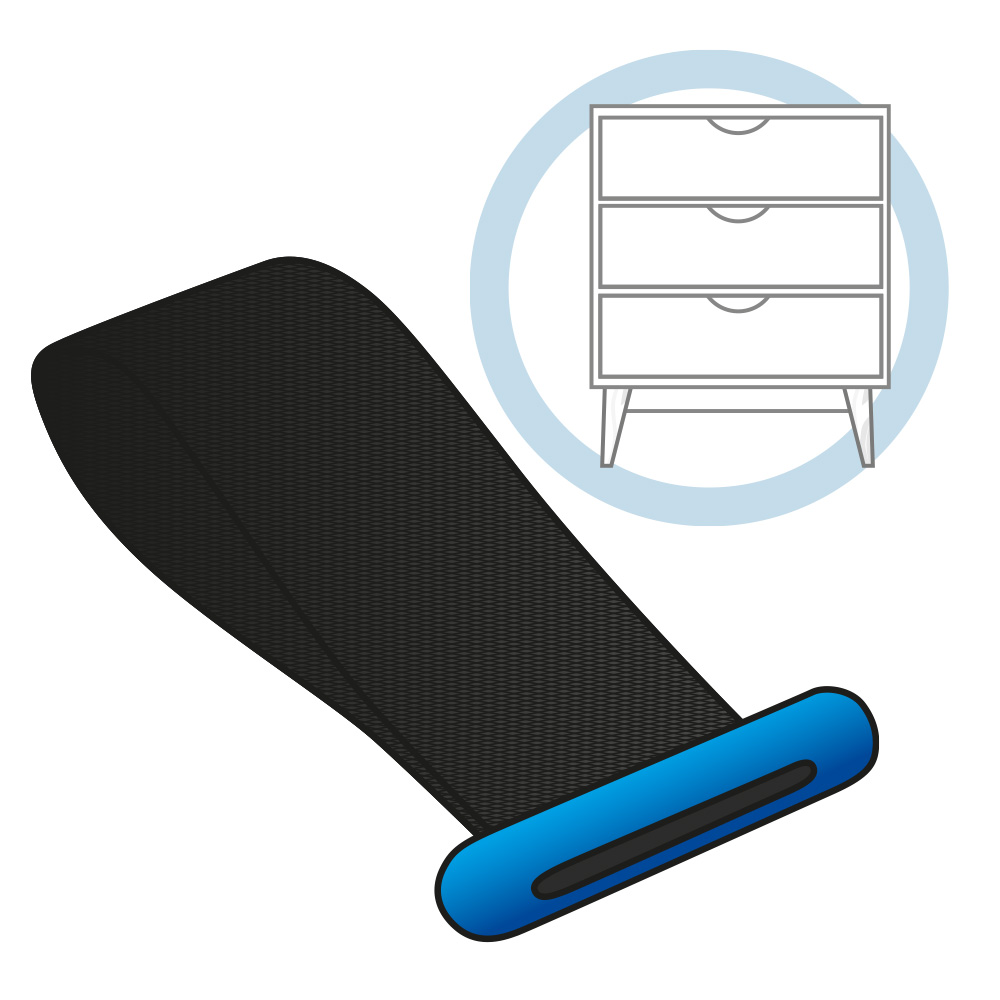

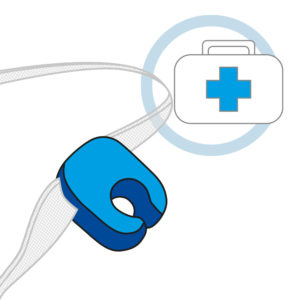

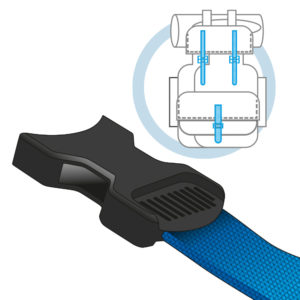

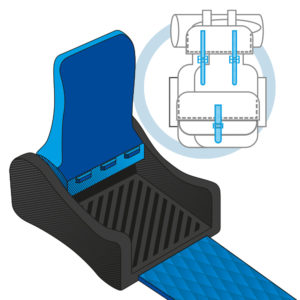

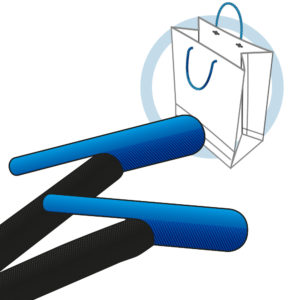

Plastic overmolding meets a number of needs : creating an aesthetic finish, adding a tip or loop for technical use (closing, assembly, locking), adding protection to improve resistance and watertightness…

We use this injection molding technique to create safety straps, lanyards, bag handles or fastening cords, based on a variety of plastic materials. We specialize in automotive overmolding for industry and safety overmolding, on straps and cords supplied by our customers or manufactured by our partners Promotress and Gauthier Fils.

Custom colors can be created using a variety of colored thermoplastics, in single- and dual-material versions. In addition, by overmolding a plastic part, it is also possible to add a brand name or logo, using a suitable mold.

We also offer plastic overmolding services to create technical parts in bimaterials.

From our workshop in France, we carry out all types of overmolding on cords, braids, straps, bungee cords, etc., either in-house or as a plastic subcontractor. Contact our team to find out more about our products and plastics processing techniques.