- Accueil

- >

- Products

- >

- Overmolding

- >

- Automotive overmolding

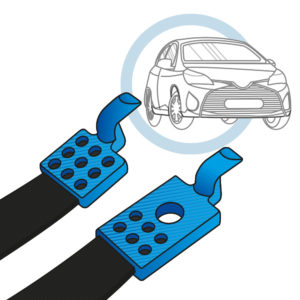

Automotive plastic overmolding

Specialists in automotive plastic overmolding, we provide a wide range of plastic finishes for cords and straps in the passenger compartment. Plastic injection molding of parts is highly precise and repeatable.

Plastic overmolding can be used to attach hooks, tips, handles, buckles and other parts to the lifting cords, turnbuckles and safety straps found in automobiles. The use of custom molds enables the creation of complex, highly resistant shapes, thanks to the choice of injected thermoplastic materials (PP polypropylene, PA polyamide, POM polyoxymethylene, etc.). A range of plastic colors is available for single- or dual-material production.

The production of plastic parts for the automotive industry is subject to strict specifications and rigorous quality control. The quality of the manufacturing process is guaranteed by the ISO 9001 standard.

Thanks to our rigor and know-how in plastic injection molding, major automotive brands have been placing their trust in us for many years. We design and manufacture parts in the chosen material, while respecting production deadlines.

We work in partnership with Promotress, a braided cord and webbing manufacturer and member of the Gauthier Group. The entire plastic injection molding process is carried out in France, in our workshop in Ambert (63).

Our automotive plastic injection specialists will be happy to tell you more about our manufacturing process, and to show you our products for industry.